The Hierarchy of Controls: A Systematic Approach to Pathogen Management

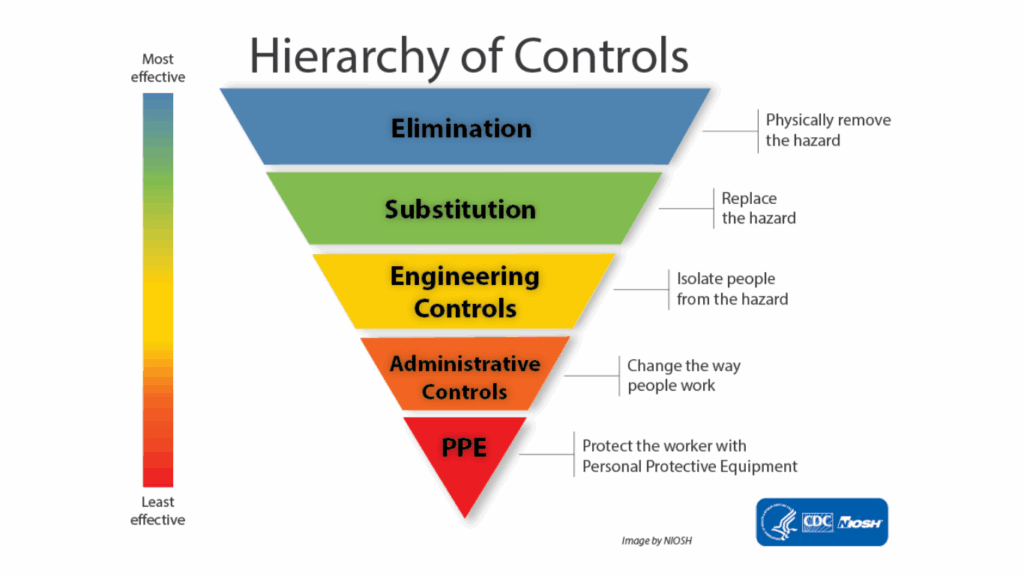

When it comes to protecting people from pathogens and other workplace hazards, not all control measures are created equal. The Hierarchy of Controls is a systematic approach that prioritizes the most effective strategies for preventing exposure to hazards, including infectious agents. What is the Hierarchy of Controls? The Hierarchy of Controls is a framework used […]

Breathe Easy: ASHRAE’s Guidelines for Better Indoor Air

Ever wonder what makes the air inside buildings healthy to breathe? ASHRAE publishes standards and guidelines for indoor air quality. Here’s what you need to know in plain language. What Are These Guidelines? Think of ASHRAE Standard 62.1-2022 as a rulebook for good indoor air in commercial facilities. It sets minimum requirements for ventilation (bringing […]