The AHR 2025 conference in Orlando was an unparalleled experience for CASPR Technologies, bringing together industry leaders, innovators, and professionals from across the HVAC sector. The event served as the perfect platform for us to connect with experts, exchange ideas, and demonstrate how CASPR’s advanced technology is setting new standards for Indoor Air Quality (IAQ). Conversations throughout the event reaffirmed what we already knew—IAQ is no longer an afterthought. It has become a fundamental pillar of HVAC system design, implementation, and maintenance. As regulatory standards continue to evolve and awareness grows, HVAC professionals are seeking proven, data-driven solutions that ensure both safety and efficiency in every environment. Our team at CASPR Technologies was proud to be at the forefront of these discussions, driving innovation and education within the industry.

The HVAC Industry is Bigger Than Ever

AHR 2025 was a testament to the rapid growth and innovation happening within the HVAC industry. Walking the show floor, we were immersed in an environment that showcased the scale, diversity, and impact of the industry’s evolution. With thousands of exhibitors and attendees, it was clear that HVAC is a driving force behind healthier, more efficient indoor environments. The range of technologies on display—from cutting-edge filtration systems to AI-driven building automation—reinforced how IAQ is now woven into the very fabric of HVAC innovation. Whether in large-scale commercial applications, residential solutions, or specialized healthcare settings, there is an increasing demand for smarter, more effective air quality solutions. CASPR Technologies’ role in this landscape was undeniable, as we demonstrated how our continuous disinfection technology is revolutionizing the way air and surfaces are treated for safety and cleanliness.

Indoor Air Quality Takes Center Stage

One of the most notable shifts at AHR 2025 was the undeniable mainstream focus on IAQ. In past years, IAQ was often viewed as an added benefit—something to consider after primary HVAC functionalities were addressed. This year, however, it was front and center in every conversation. Whether discussing air purification, improved filtration, or next-generation pathogen treatment, professionals across the board recognized that effective IAQ solutions are essential for occupant health and safety.

Moreover, we had the opportunity to engage with engineers, facility managers, and industry decision-makers who were all eager to learn how they could integrate validated, long-term IAQ solutions into their existing systems. Our team emphasized the importance of maintaining both air and surface cleanliness, as pathogen mitigation strategies must go beyond traditional approaches to create truly safe indoor environments. As regulatory bodies continue to set stricter standards for indoor air quality, it’s clear that data-backed, continuously active solutions like CASPR’s are becoming a necessity rather than an option.

CASPR Technologies at AHR 2025 Takeaways: The Growing Importance of Pathogen Treatment

At AHR 2025, pathogen treatment emerged as one of the most pressing topics in IAQ discussions, highlighting a growing industry-wide realization: true disinfection goes beyond air filtration—it must also address surface contamination. While traditional HVAC solutions have focused primarily on airborne pollutants, there is now an increasing demand for comprehensive, real-time mitigation strategies that tackle both airborne and surface-borne pathogens.

As awareness grows around the role of pathogens in indoor environments, industry professionals are actively seeking proven solutions that don’t just capture contaminants but actively neutralize them. CASPR Technologies’ continuous disinfection technology captured the attention of engineers, facility managers, and HVAC specialists alike, who recognize that passive filtration alone is no longer enough. The ability to provide ongoing, automated pathogen reduction—without the use of chemicals or manual intervention—is becoming a critical requirement for modern IAQ strategies.

Pathogen mitigation is no longer a reactive measure—it’s a proactive necessity. Schools, hospitals, commercial buildings, and residential spaces alike are prioritizing IAQ solutions that offer real-time, continuous protection against bacteria, viruses, and mold. Professionals expressed a strong desire for technologies that are not only validated by scientific data but also seamlessly integrate into existing HVAC systems without requiring costly modifications or downtime.

The consensus was clear: effective, real-time pathogen mitigation is no longer just a competitive advantage—it’s an essential component of any serious IAQ strategy. As regulations tighten and industry standards evolve, there is a heightened expectation for continuous, scientifically backed solutions that can proactively reduce pathogens in the air and on surfaces.

ASHRAE 241 and the Need for More Data

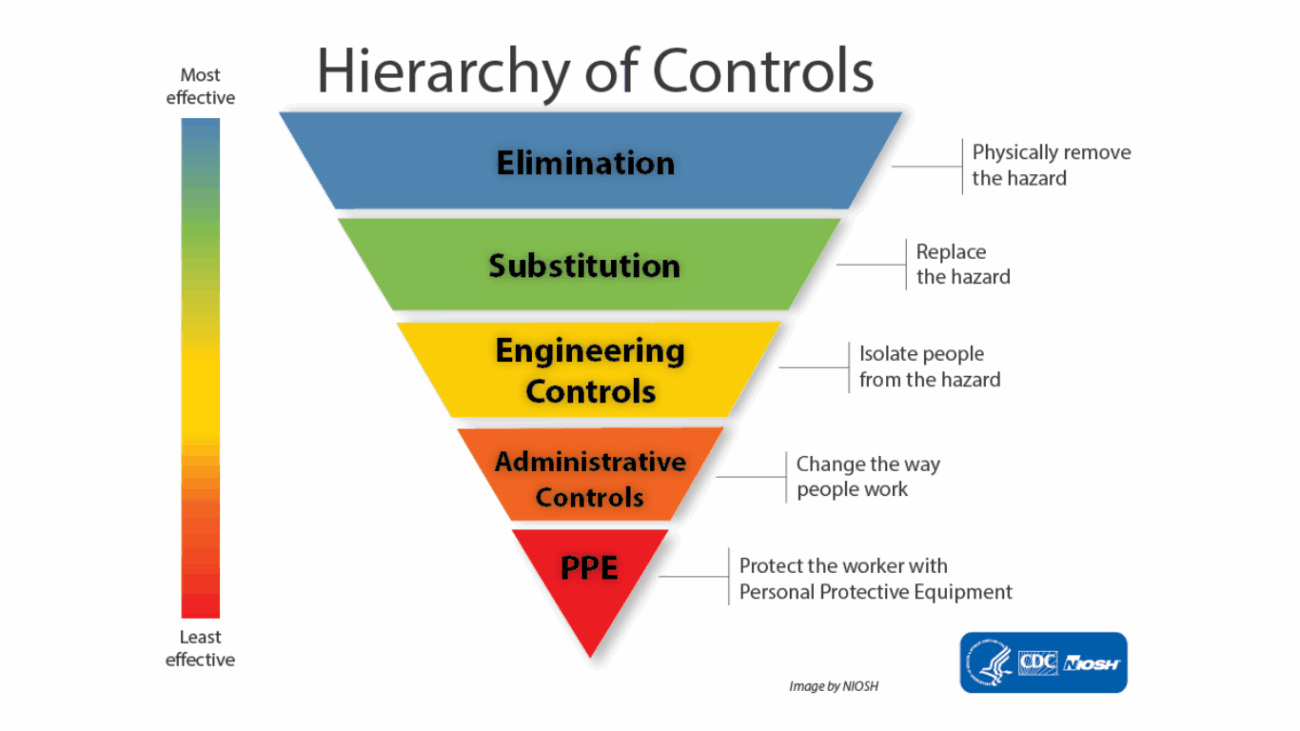

A crucial industry discussion at AHR 2025 centered around ASHRAE 241, a new standard designed to provide guidelines for pathogen mitigation in indoor environments. While there is a growing push for IAQ advancements, one major challenge remains—the lack of published data for many existing technologies. Industry leaders stressed the importance of transparency in testing, safety validation, and efficacy reporting to ensure that businesses and consumers can make informed decisions about the technologies they implement.

“I was surprised to find out how little people knew about IAQ standards and how a lot of the industry has no testing,” stated CASPR Representative Roberto Bonilla.

CASPR Technologies has long been committed to setting the benchmark for industry standards. As part of our mission to deliver scientifically validated solutions, CASPR was the first technology to be tested for both safety and efficiency under ASHRAE 241 standards. This commitment to data-driven innovation positions CASPR Technologies as a trusted leader in the IAQ space, providing stakeholders with real, measurable results that demonstrate the true impact of our technology.

CASPR Technologies at AHR 2025: A Packed Room and Engaging Conversations

One of the highlights for CASPR Technologies at AHR 2025 was the overwhelming turnout for our paper presentation, ‘Assessing Indoor Air Quality in a Comparative Study Among ASHRAE Ventilation Standards Compared to a Control with a Continuous Active In-Room Air Cleaning Device.’ With over 120 industry professionals in attendance, the room was filled with engineers, facility managers, and HVAC experts eager to dive deeper into IAQ advancements.

The level of engagement and thoughtful questions from attendees reinforced that IAQ is no longer an afterthought—it’s a critical priority for the industry. Throughout the presentation, we discussed the importance of data-driven decision-making in IAQ solutions and how continuous active air cleaning devices can complement ASHRAE ventilation standards. The discussions that followed were not only insightful but also highlighted the growing demand for validated, real-world data on the effectiveness of air purification technologies.

Many professionals expressed keen interest in how CASPR’s continuous disinfection solutions could be integrated into their existing HVAC systems to enhance air quality and pathogen mitigation. The enthusiasm and dialogue that emerged from this session demonstrated the need for transparent testing, standardized guidelines, and proven results in IAQ technology—something CASPR is committed to delivering.

AHR 2025 provided the perfect platform to engage with industry leaders and share groundbreaking research, and we’re excited to continue these conversations as we push the boundaries of IAQ innovation.

Innovation at Every Level

Innovation in HVAC isn’t just about upgrading large-scale systems—it’s about refining and enhancing every individual component to create a more efficient and effective IAQ strategy. From advanced sensors that monitor air quality in real time to next-generation filtration technologies that capture even the smallest particulates, the industry is experiencing a wave of breakthroughs designed to optimize air circulation, purification, and disinfection. Engineers and manufacturers are focusing on smarter, more adaptable solutions that integrate seamlessly into both new and existing HVAC infrastructures, making high-quality indoor air more accessible than ever before. These advancements are not just about compliance with evolving standards—they are about fundamentally reshaping how we think about air quality in homes, offices, hospitals, and public spaces.

At CASPR Technologies, we are thrilled to be part of this movement, pioneering continuous disinfection technology that works in tandem with HVAC systems to ensure that indoor environments remain as safe and healthy as possible. Unlike traditional air treatment methods that rely on passive filtration alone, our technology actively neutralizes pathogens in the air and on surfaces, providing a comprehensive approach to IAQ improvement. Whether it’s for schools, healthcare facilities, commercial spaces, or residential buildings, our goal is to make clean, purified air the standard, not the exception. By pushing the boundaries of what’s possible in HVAC and IAQ innovation, CASPR Technologies is committed to shaping the future of indoor air quality—one breakthrough at a time.

CASPR Technologies AHR 2025: A Successful Event with a Bright Future

Reflecting on our experience at AHR 2025, one thing is clear—the future of IAQ has never been stronger. The sheer level of interest, engagement, and collaboration we witnessed at the event speaks to the growing demand for innovative air quality solutions. The industry is evolving rapidly, and businesses are prioritizing health-focused, sustainable technologies more than ever before.

For CASPR Technologies, this event was more than just an opportunity to showcase our technology—it was a chance to be part of an industry-wide movement towards better, safer indoor environments. The connections we made, the conversations we had, and the enthusiasm we witnessed all point to an exciting future for IAQ innovation.

To everyone who stopped by our booth, attended our presentation, and engaged with us in meaningful discussions—thank you. Your passion and curiosity inspire us to continue pushing the boundaries of what’s possible in IAQ and HVAC technology. We look forward to the future, knowing that together, we can redefine indoor air quality and make every indoor space a safer place to live and work.