The Evolution of IAQ Monitoring: Past, Present, and Future

The Early Days: Temperature-Only Monitoring If you go back in time, the original indoor air quality (IAQ) sensors only measured temperature and were usually tied into the thermostat to control the HVAC system. These basic IAQ monitoring sensors/thermostats served a single purpose: maintaining comfortable temperatures in indoor spaces. They operated on simple principles detecting when […]

Designing for Indoor Air Quality: VOCs, Particulate Matter, and Pathogens

The Indoor Air Quality Challenges of Exhibition Spaces During a recent visit to a large convention center, I spoke with the engineering team about their indoor air quality challenges. One engineer highlighted a unique issue: installing thousands of yards of new carpet for exhibitions leads to significant VOC surges. We explored solutions ranging from temporary […]

Active vs. Passive: Which Approach Wins the Indoor Air Quality Battle?

When faced with a physical confrontation, there are two instinctive choices: stand your ground and engage or create distance and defend. This same dynamic plays out in the ongoing battle of bettering indoor air quality (IAQ), where we can choose between either a passive or an active approach to air purification. Which approach are you […]

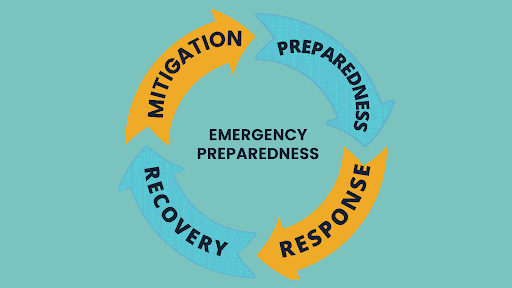

Rethinking ASHRAE 241: Should Emergency Air Standards Become the New Normal?

In recent research on ASHRAE 241, we came across a thought-provoking article titled “Pandemic-Proofing Our Air: How Standard 241 Makes Indoor Air Safer” (Occupational Health & Safety, 2024). While much of the discussion around ASHRAE 241 focuses on emergency preparedness, it raised an intriguing question: What if these enhanced air quality standards became the daily […]

Leveraging Smart Sensors for Better Indoor Air Quality: A Facility Manager’s Guide

Indoor air quality (IAQ) has become a critical focus for facility managers and engineers, as it directly impacts occupant health, comfort, and productivity. Smart sensor technology is revolutionizing this effort by providing real-time data on air pollutants, humidity levels, temperature, and ventilation performance. Let’s explore how these powerful technologies can transform your facility’s air quality […]

Efficacy and Safety: Critical Partners in Disinfection Technology

When selecting disinfection methods for mechanical systems, both efficacy and safety demand equal attention. While many focus primarily on a system’s ability to eliminate pathogens, the safety implications of these technologies can make or break their real-world viability. The ASHRAE 241 standard addresses this crucial balance by providing comprehensive testing protocols for both effectiveness and […]

CDC Guidelines: The Importance of Air Exchange for Health Safety

Understanding the CDC’s Role As America’s frontline defense in public health protection, the Center for Disease Control and Prevention (CDC) is the nations’s leading public health institution. T he CDC’s mission encompasses everything from disease prevention to public health guidance. Their expertise spans multiple areas, including: Monitoring and responding to disease outbreaks both domestically and globally […]

ASHRAE 241: Understanding the Standardized Testing Protocol

The introduction of ASHRAE 241 marks a significant advancement in how we evaluate indoor air cleaning technologies. While our previous post provided a comprehensive overview of the standard, we’ll dive deep into its groundbreaking testing protocol and why it matters for facility managers, building owners, and indoor air quality professionals. The Problem with Traditional Testing […]

Combating Student Absenteeism Through Advanced Disinfection Strategies

Combating Student Absenteeism Through Advanced Disinfection Strategies In an era where educational outcomes are critically linked to student attendance, school districts are increasingly recognizing the powerful connection between robust disinfection protocols and reduced absenteeism. This makes implementing effective disinfection strategies not just a health priority, but an academic and financial imperative. The stakes are high: […]

Beyond Air Disinfection: A Comprehensive Approach to Pathogen Control

Since the pandemic, facilities worldwide have prioritized indoor air quality through various disinfection strategies. However, an important question remains: Is air disinfection alone sufficient to protect against the full spectrum of infectious pathogens? The Challenge of Surface Pathogens While airborne pathogens capture much attention, several dangerous microorganisms primarily spread through surface contact. Common surface pathogens […]