Rethinking ASHRAE 241: Should Emergency Air Standards Become the New Normal?

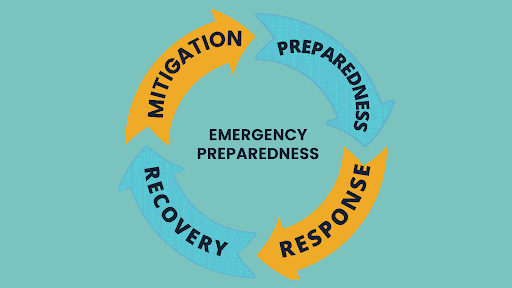

In recent research on ASHRAE 241, we came across a thought-provoking article titled “Pandemic-Proofing Our Air: How Standard 241 Makes Indoor Air Safer” (Occupational Health & Safety, 2024). While much of the discussion around ASHRAE 241 focuses on emergency preparedness, it raised an intriguing question: What if these enhanced air quality standards became the daily […]

CASPR Technologies to Launch New Residential Product Line at 2025 ASHRAE Winter Conference

CASPR Technologies to Launch New Residential Product Line at 2025 ASHRAE Winter Conference Company’s Chief Medical Consultant to Present Groundbreaking Paper on Indoor Air Quality Standards Orlando, FL – (Jan. 16, 2025) – CASPR Technologies, a leader in continuous air and surface disinfection technology, is excited to announce its breakthrough advances in science and air […]

Leveraging Smart Sensors for Better Indoor Air Quality: A Facility Manager’s Guide

Indoor air quality (IAQ) has become a critical focus for facility managers and engineers, as it directly impacts occupant health, comfort, and productivity. Smart sensor technology is revolutionizing this effort by providing real-time data on air pollutants, humidity levels, temperature, and ventilation performance. Let’s explore how these powerful technologies can transform your facility’s air quality […]

Efficacy and Safety: Critical Partners in Disinfection Technology

When selecting disinfection methods for mechanical systems, both efficacy and safety demand equal attention. While many focus primarily on a system’s ability to eliminate pathogens, the safety implications of these technologies can make or break their real-world viability. The ASHRAE 241 standard addresses this crucial balance by providing comprehensive testing protocols for both effectiveness and […]